AIR CONDITIONERS

Even on the hottest and most humid days in the RGV, an energy-efficient air conditioner can keep your home cool, comfortable and energy-smart. The most common type of central air conditioning unit is the “split system.” Commonly in a “split system,” refrigerant circulates between an indoor coil and an outdoor coil. The refrigerant cools the air, dehumidifying it in the process; a blower circulates air through ducts throughout the house. A thermostat maintains the temperature at the setting you select. A variation is the “heat pump” a type of system that functions as heater and air conditioner.

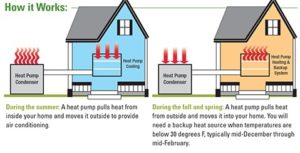

HEAT PUMPS

Conventional air conditioning units use an electrical coil or gas furnace to heat your home. Multi-purpose heat pumps can heat or cool your home quietly, efficiently and effectively with the same technology that cools your house. These can come in the form of a split system with or without ductwork. A split system without the use of ductwork is known as a “mini-split”.

Perfect for spaces like add-on rooms where installing ductwork isn’t practical, mini-split systems provide a flexible and efficient heating and cooling solution. Split ductless systems have an outside condenser and compressor, and one or more indoor blower units, called air handlers, mounted high on the wall that distribute air. The indoor and outdoor sections are connected by a thin conduit that houses the power cable, refrigerant tubing, and a condensate drain. Each air handler cools the room in which it’s installed, and you set the temperature with a remote control. Split ductless systems can be more expensive than window air conditioners, and professional installation is recommended. While not technically central air, the cooling they provide can feel like a central air system.

TERMINOLOGY

Size & Tonnage

The air conditioner’s cooling capacity, size is measured in British thermal units per hour (Btu/hr.) or in “tons.” One ton of cooling equals 12,000 Btu/hr.

The easiest place to find out the “size” of your unit is to look at the AC unit itself. Go outside to the condensing unit and look for a data plaque mounted to the side. Find the model number. Normally within this string of letters and numerals, you should find an even, two-digit number.

- 18 = 1.5 tons

- 24 = 2 tons

- 30 = 2.5 tons

- 36 = 3 tons

- 42 = 3.5 tons

- 48 = 4 tons

- 60 = 5 tons

EFFICIENCY

This describes how much cooling the unit delivers for each watt of electricity. Efficiency is expressed as the seasonal energy-efficiency rating, or SEER. The minimum SEER for a split system central air conditioner allowed today is 14, so look for units with SEER ratings of 15 or greater. The higher the SEER, the more you can lower your energy costs. How much will you save with a higher SEER unit? Check out this calculator here to compare the difference.

UPGRADING

If you’re upgrading your central air, don’t assume you should buy the same-sized system. Any changes you’ve made to improve your home’s energy efficiency, such as upgrading your windows or adding insulation, can reduce your cooling needs. On the other hand, if you’ve added rooms, you might need more cooling.

Programmable Thermostat

Programmable thermostats can reduce your cooling costs by about 10 percent. And using a box or ceiling fan, which costs little to run, can make you feel 3° F to 4° F cooler. You can sometimes get an ENERGY rebate if you choose to install a programmable thermostat.

What is SEER?

SEER stands for Seasonal Energy Efficiency Ratio.

Every air conditioner and heat pump comes with a SEER rating, which represents the unit’s energy efficiency. Generally, the higher the HVAC SEER rating, the more efficient the unit and the less energy it consumes. This means A/C energy savings for your customers, and a great selling point for your tech.

Since 2015, national energy efficiency standards require a minimum SEER rating on all air conditioners and heat pumps sold and installed. While older HVAC equipment may have an 8 or 9 SEER rating, modern units typically range from 13 or 14 SEER as a minimum (regulations vary by state) and 21 to 25 SEER as a maximum.

Another round of national energy efficiency standards for residential central AC and heat pumps goes into effect in 2023.

But, there’s more to helping customers choose the best central air system or heat pump than simply picking a unit with the highest SEER rating. Our SEER Rating Calculator determines costs and A/C energy savings based on a specific HVAC formula.

How to Calculate SEER Energy Savings

To calculate SEER, this calculator uses four factors to determine how much a customer could potentially save on energy costs by upgrading to a unit with a higher HVAC SEER rating:

-

SEER rating of customer’s current air conditioner or heat pump.

Look for the bright yellow and black “EnergyGuide” rating tag on the side of the customer’s outdoor condenser or indoor air handler; or record the system’s model number and serial number, then contact the manufacturer

-

Size (in tons) of customer’s current air conditioner or heat pump.

Although some companies refer to tonnage as the size of the A/C or heat pump, the term represents the unit’s cooling capacity—how much heat the unit removes from a house or business in one hour. For example, a 1-ton air conditioner can remove 12,000 BTUs of heat from a home in one hour, while a 2-ton air conditioner can remove 24,000 BTUs.

-

Cost of electricity per kilowatt-hour (Kwh) in your state.

The national average of electric energy costs $0.14 per kilowatt hour. Click here to find your state’s current electricity rate.

-

Estimated annual cooling or heating hours for customer’s location.

The national average of unit operation equals 2,100 hours per cooling season. Seasonal changes and different climates for each region often dictate how many hours a customer’s system needs to run during a typical cooling season. If possible, review the past few years of the customer’s annual usage and figure the average operating time per year.

The SEER Rating Savings Calculator then compares that existing data with a higher-efficiency air conditioner or heat pump to show customers A/C energy savings over a year, five years, or longer to demonstrate ROI on new cooling equipment.

SEER Formula + Example

Simply put, the SEER rating calculation formula represents the ratio of the cooling output of an air conditioner or heat pump over a typical cooling season, divided by the energy it consumes in kilowatt hours.

Using the factors outlined above, we can utilize the SEER formula to compare the cost savings for a 3-ton A/C unit with an 9 SEER rating to a 3-ton A/C unit with a 16 SEER rating.

Assuming the electricity cost is $0.14 per Kwh and the A/C runs 2,100 hours per cooling season, the customer would save $514 per year on energy expenses.

A good SEER rating for most cooling systems ranges from 14 SEER to 16 SEER, with a higher-rated unit offering slightly more efficiency, but also costing a little more. Compare different HVAC SEER ratings and potential savings with our 14 SEER vs. 16 SEER calculator.

SEER Rating Chart

Think of an A/C SEER rating in terms of buying a car with a high MPG (miles per gallon). If you operate that vehicle exactly as the manufacturer intended, you’re likely to see value in fuel savings. If you drive it like Mario Andretti, those savings will quickly evaporate. The same goes for your customers’ home or business cooling systems.

Installing an incorrectly sized air conditioner or heat pump for a customer wastes time and money. An A/C unit that’s too large for the space might start short-cycling, which occurs when the compressor fails to run long enough to dehumidify the home or business. It causes the system to cycle on and off more than necessary. A too-small system also runs too much to match the thermostat cooling setting and wears out faster.

ServiceTitan’s SEER Savings Calculator takes the guesswork out of energy savings for your customers considering a new cooling unit, so you can clearly communicate the potential benefits to improve your company’s sales.

AFUE Energy Savings Calculator: Quantify Furnace Efficiency

Nearly half of all homes in the U.S. use natural gas as the primary heating fuel, and energy experts forecast a 30% increase in heating bills this winter, largely due to the rising retail prices of natural gas.

To help your HVAC customers reduce those high-energy costs during the winter, your techs can explain the benefits of installing a new high-efficiency furnace, and show them how much money they can save with ServiceTitan’s AFUE Energy Savings Calculator.

What is AFUE?

AFUE stands for Annual Fuel Utilization Efficiency.

Every new furnace powered by fuel (natural gas, propane, oil, etc.) comes with an AFUE rating, which measures the percentage of fuel converted into heat. The higher AFUE, the lower the heating costs.

For instance, an 80 AFUE furnace converts 80% of its fuel into heat, but wastes 20% through air leaks or inefficient design. A 95 AFUE furnace converts 95% of its fuel into heat, but wastes 5%, and so on.

First developed by ASHRAE (American Society of Heating, Refrigerating and Air Conditioning Engineers), AFUE serves as the national standard of measurement for combustion efficiency used by the U.S. Department of Energy. This federal agency sets the minimum AFUE for gas furnaces at 90% for the Northern region and 80% for the Southwest and Southern regions.

Most high-efficiency furnaces today come with a 90 AFUE rating or higher, and some top-of-the-line models offer AFUE savings of up to 98%. This translates into real savings on utility bills for your customers—and a great selling point for your techs.

Just keep in mind, AFUE measures furnace efficiency, whereas Seasonal Energy Efficiency Ratio (SEER) measures the energy efficiency of cooling systems, like air conditioners and heat pumps (used to heat and cool).

How to Calculate AFUE Savings

AFUE represents the amount of fuel used to create heat, or the percent of heat produced for every dollar of fuel consumed.

To calculate the AFUE percentage, you divide the amount of fuel supplied to the furnace by the amount of heat produced by the unit—typically measured in BTUs or British Thermal Units. The average household, especially in the Northern region, needs about 100 million BTUs during a normal heating season.

In its Winter 2020-2021 outlook, the U.S. Energy Information Administration (EIA) forecasts a 30% increase in heating costs for U.S. households that primarily use natural gas for space heating, with most consumers expected to spend an average of $746 on heating this winter.

To understand BTUs as they relate to AFUE, think of it in these terms: A heating system with a 90% AFUE rating means that nine-tenths of every BTU of energy used to run the furnace is returned to the home or business as usable heat. Again, the higher AFUE, the higher the savings.

To use our energy savings calculator to determine AFUE for heating efficiency, ServiceTitan considers four factors to determine how much a customer could potentially save on energy costs by upgrading to a high-efficiency furnace with a higher HVAC AFUE rating:

1. AFUE efficiency rating of customer’s current furnace.

Look for the AFUE rating on the bright yellow-and-black EnergyGuide label on the side of the customer’s furnace. If you can’t locate the EnergyGuide label, try checking the owner’s manual or record the system’s model number and serial number, then contact the manufacturer.

Keep in mind that heating equipment becomes less efficient over time, so educate customers about the value of getting an accurate efficiency rating reading from an HVAC professional or leading HVAC company.

Note: If customers use heat pumps for heating homes and businesses, you’ll need to check the heating seasonal performance factor (HSPF) rating tag on the side of the customer’s unit. SEER for heat pumps works similarly to air conditioners, as they both use electricity (not fuel) and are sized based on how many BTUs they produce.

The main difference between SEER and AFUE is SEER compares BTUs with watt-hours and AFUE compares BTUs with BTUs.

2. HVAC load calculation.

The HVAC load calculation shows you the exact amount of BTUs that a certain space requires for sufficient heating. It identifies the square footage of each room or the whole house to determine the capacity—BTUs per hour—needed to reach the desired indoor temperature.

While the Manual J residential calculation provides the most accurate sizing for an HVAC unit, technicians can use this HVAC Load Calculator to determine a general estimate in the field.

3. Cost of natural gas per thousand cubic feet (MCF) in your state.

According to the EIA, retail natural gas prices in the United States are expected to rise, on average, from $10.17 per thousand cubic feet (MCF) last winter to $12.93/MCF this winter, the highest price in 15 years. The EIA expects the largest increase in retail natural gas prices to occur in the Midwest, where prices may rise to $11.28/MCF, a 45% increase compared with last winter. Click here to find your state’s current natural gas price.

4. Estimated annual heating hours for customer’s location.

Seasonal changes and different climates for each region often dictate how many hours a customer’s system needs to run during a typical heating season. Generally, climates with cold and wet conditions tend to need heating longer than warm and dry climates. If possible, review the past few years of the customer’s annual usage and figure the average operating time per year.

The AFUE Energy Savings Calculator then compares that existing data with a higher-efficiency gas furnace to show customers energy savings over a year, five years, or longer to demonstrate ROI on a new natural gas-powered furnace.

AFUE Formula + Example

To calculate the AFUE percentage, you divide the amount of fuel supplied to the furnace by the amount of heat (BTUs) produced by the unit. The calculator computes how much per year the customer is spending on heating costs based on three primary factors:

-

The type of fuel used in the customer’s current heating system.

-

The AFUE rating on the customer’s unit.

-

The unit’s BTU input capacity or tonnage.

The calculator then compares the customer’s current heating system with a new one. Here are two examples:

60 AFUE vs. 80 AFUE—25% saved per year

-

5-year savings: $2,506

-

10-year savings: $5,012

-

15-year savings: $7,518

60 AFUE vs. 90 AFUE—33% saved per year

-

5-year savings: $3,341

-

10-year savings: $6,682

-

15-year savings: $10,023

AFUE Rating Chart

Think of an AFUE rating in terms of buying a car with a high MPG (miles per gallon). If you operate that vehicle exactly as the manufacturer intended, you’re likely to see value in fuel savings. If you drive it like Mario Andretti in the Indy 500, those savings will quickly evaporate. The same goes for your customers’ home or business heating systems.

AFUE Energy Savings Calculator takes the guesswork out of energy savings for your customers considering a new furnace, so you can clearly communicate the potential benefits to improve your company’s sales.

Disclaimer Statement

*The recommended values are in good faith and are solely meant for generic, informative purposes. We do not guarantee the accuracy of this information. Please note that other external factors may affect or falsify the recommendations. For accurate results, consult a professional.

How To Calculate HVAC Load

The Manual J residential calculation is actually the proper method for sizing an HVAC unit—a technique designed by the Air Conditioning Contractors of America (ACCA). This calculation is commonly performed with complex computer programs, which require time, energy, and money. That’s why contractors have developed the BTU calculator as a rule of thumb. That way, technicians can determine a general estimate while in the field. An accurately sized HVAC unit will ensure that the desired space can reach the right temperature without wasting energy. This is how you find that perfect number.

Step One:

Determine the square footage of the home. You can either find this in the home’s blueprint or measure out the space room-by-room. Start by taking the length and width of each room and multiplying those measurements to calculate the square footage of that room. Add up the square footage of each room—and there you have it! Another way to do this is by taking exterior measurements of the entire house and subtracting the square footage of any part of the home not intended to be cooled or heated—like a basement or garage. Make sure to account for the height of the room, as well. Rooms with tall ceilings tend to demand more BTUs than one with a standard height.

Step Two

Account for factors that affect insulation. Check to see what grade of insulation the home was built with. If you are unsure, U.S. Standard Insulation is probably your best bet. Other key factors that need to be taken into consideration are sun exposure, windows, and airtightness for the entire home. Common factors to be accounted for include:

-

Each person living in a home = 100 additional BTUs

-

Each window in a home = 1,000 additional BTUs

-

Each exterior door in a home = 1,000 additional BTUs

Step Three:

Think about how the living space is being used. Does this home or particular room have heat-producing appliances? How many people regularly occupy the space you are calculating? This should also inform the HVAC load that will be sufficient to heat or cool the intended area.

Cooling Load Calculation Example

To calculate the estimated HVAC load for a house with 2,500 square feet, 12 windows, and 3 exterior doors occupied by 4 people, simply plug it into this formula:

-

2,500 x 25 = 62,500 base BTU

-

4 people x 400 = 1,600

-

12 windows x 1,000 = 12,000

-

3 exterior doors x 1,000 = 3,000

-

62,500 + 1,600 + 12,000 + 3,000 = 79,100 BTU

Disclaimer Statement

*The recommended equipment capacities are estimated in good faith and are solely meant for generic, informative purposes. We do not guarantee the accuracy of this information. Please note that other external factors may affect or falsify the recommended BTUs. For accurate values, consult a licensed engineer.

Free Online Ductulator Tool

A duct size calculator, commonly known as a ductulator, depends on factors like the size of the space you’re heating or cooling, air flow velocity, friction loss, and available static pressure of the HVAC system. Save time on the job and do less manual math by using our free, online ServiceTitan Ductulator to easily calculate the right size duct for your projects.

Below we walk through the various formulas you will need to compute, and enter into the duct calculator.

Figure Square Footage of Spaces

A duct sizing chart relies foremost on the square footage of a home or office space—but, more importantly, the size of each individual room within the building.

To calculate the area of a rectangular or square room, simply multiply the length and width of the room. You can also refer to a building’s blueprint, zoning drawings on file with the local planning office, or a recent real estate listing for the space, if available.

So, if a room measures 10-by-10 feet, the total area equals 100 square feet. For rooms that aren’t perfectly square or rectangular, such as an L-shaped space, split the room into sections and total the area of each section.

Determining Air Duct Sizing by Velocity of Air

Air velocity, or airflow, gets measured in cubic feet per minute (CFM) and is directly proportional to the size of ductwork. You must find the duct CFM of each room to figure out the size of air ducts to install. It’s important to do room-by-room calculations, otherwise temperatures will likely measure uneven throughout the house or office.

To calculate the duct CFM for each room, you must first perform an HVAC load calculation for the whole house and for each room, using the Manual J method.

Use the free HVAC Load Calculator to figure the exact amount of BTUs per hour each room requires for sufficient heating and cooling, as well as the load capacity required for the entire house or building.

Size of HVAC Unit Required

You also must determine which size of HVAC equipment will work best to meet the energy demands for the space, based on your whole-home or whole-office HVAC load calculations.

To calculate the required equipment size, divide the HVAC load for the entire building by 12,000. One ton equals 12,000 BTUs, so if a house or office needs 24,000 BTUs, it will take a 2-ton HVAC unit. If you get an uneven number, such as 2.33 for a 28,000 BTU load capacity, round up to a 2.5-ton unit.

To use the duct CFM calculator, you must next calculate the equipment’s estimated airflow in CFM. Multiply the tonnage required (that you just calculated above) by 400 CFM, which is the average output of an HVAC unit. For a 2-ton HVAC unit, the equipment CFM totals 800.

NOTE: The average airflow output in cooling mode is between 350 and 400 CFM. Heating season airflow requires approximately 65 percent of the airflow needed for cooling. Therefore, to ensure there’s adequate airflow for both cooling and heating, use the high-end threshold of 400 CFM when referencing a duct sizing chart CFM resource.

Duct CFM Calculation Formula

Once you do the load calculations and figure out the equipment output required, apply this duct CFM calculation formula to determine each room’s demand:

Room CFM = (Room load/Whole house load) ✕ Equipment CFM

As an example, say Room A needs 2,000 BTUs of heat gain based on HVAC room-by-room load calculations, and the home overall needs 24,000 BTUs, which requires a 2-ton furnace with a velocity of 800 CFM.

24,000 BTUs ÷ 12,000 BTUs in 1 ton = 2 tons ✕ 400 CFM per ton = 800 CFM

Room A = (2,000 BTUs ÷ 24,000 BTUs) ✕ 800 CFM

Room A = 66.67 CFM

TIP: Approximately 1 CFM of air is required to heat or cool 1 to 1.25 square feet of floor area. It takes closer to 2 CFMs to cool rooms with a lot of windows or direct sunlight.

Figure the Friction Loss Rate

Friction rate (FR) helps you decide the diameter and shape of ductwork you can use without negatively impacting optimal air flow. It’s calculated by using the available static pressure (ASP) divided by total effective length (TEL) and multiplied by 100 to show how much pressure drop the system can accommodate per 100 feet of effective length. You want a higher friction rate, because it means you can use smaller, more restrictive ductwork than on an HVAC project designed with a lower friction rate, which requires larger ducts. With a low friction rate, one faulty component can severely hamper air flow because there’s less room for error.

Refer to the duct CFM chart in the HVAC manufacturer’s specs to determine the external static pressure of the blower for that specific HVAC model. It’s typically displayed as a CFM chart for HVAC that breaks down different blower settings and total CFMs required for the house or building.

The Total External Static Pressure (TESP) gets measured in inches of water column (wc or iws). As a rule of thumb, the majority of systems have a default friction rate of .05” wc, so you can use that average rate as your friction rate, calculate it using a ductulator chart, HVAC duct sizing software, or figure the friction rate yourself to get a more accurate measurement.

From there, deduct the pressure drops created by any components you plan to add to the air distribution system, such as external coils, filters, grills, registers, and dampers. The Manual D method, which focuses on how to design duct systems, suggests using 0.03 iwc for a supply register, return grille, and balancing damper. Air filters typically list estimated pressure drop on the product packaging or the manufacturer’s website.

That deduction gives you the available static pressure (ASP), or static pressure budget, you’re working with when designing the duct system. You cannot exceed the ASP or the system will deliver improper airflow and cause equipment problems over time.

ASP impacts HVAC ductwork sizing. The less static pressure available, the larger the ductwork required. If projected velocity seems too high for the system, select the next-largest duct size.

Total Effective Length of Ductwork

The total effective length (TEL) equals the measured length from the farthest supply outlet, through the equipment, and to the farthest return outlet—plus the equivalent lengths of all turns and fittings. Friction rate gets calculated based on the pressure drop per 100 feet.

TEL takes into account the pressure drops that will happen from splits, turns, and other fittings in the HVAC ductwork plan. Instead of trying to calculate all of those individual instances of pressure loss, HVAC professionals measure the length of straight duct run that would create the same pressure drop, which is called effective length. Each fitting has an effective length that equates its pressure drop to an equivalent amount of straight duct.

To configure TEL, add up the effective lengths of all fittings in the most restrictive run and add that number to the length of the straight sections between the return and supply in that run. Once you know the TEL, you’re ready to calculate friction rate, which an HVAC duct sizer tool uses to size all duct trunks and branches.

Friction Rate = (ASP X 100) ÷ TEL

Here’s an example the friction rate calculation:

Measured length of straight duct = 50 feet

Equivalent lengths of turns and fittings between the start and end of straight duct: 150 feet

50’ + 150’ = 200 feet TEL

External static pressure of air handler @ 1000 CFM = 0.5” wc

Subtract static drops for components = 0.03” wc for register, 0.03” wc for grille, and 0.15” wc for filter: 0.5 - 0.03 - 0.03 - 0.15 = 0.29” wc ASP

Friction Rate = (0.29 ✕ 100) ÷ 200 = 0.145’ wc

Other Details for Duct Sizing Calculator

There are a few other important factors to consider when using a free HVAC duct sizing calculator to determine HVAC duct dimensions and sizing, such as ducting material type. Do you plan on installing an HVAC rectangular duct or round duct?

Keep in mind, duct material choice also affects airflow resistance and static pressure, therefore calculations for flexible duct sizing differ slightly from sheet metal ductwork. Flex duct CFM will measure less than the airflow in sheet metal and for coated fiberglass duct board. Rigid sheet metal provides the least airflow resistance. Flex duct CFM changes based on how it’s installed, with performance drastically reduced if not completely stretched out, or with sharp turns and twists.

In the Ductulator, select the type and shape of duct you plan to use to get the correct corresponding measurements in the duct size chart.